Hello everyone,

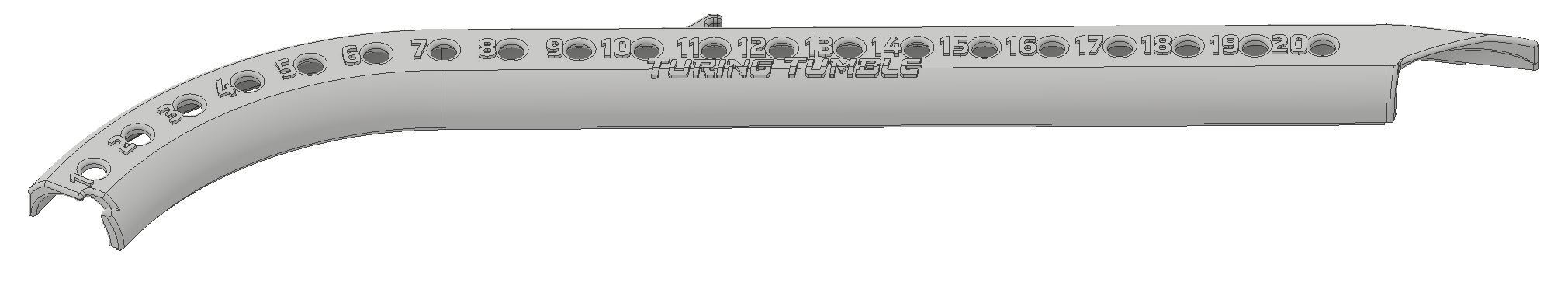

Thank you all for your ideas! They’re fantastic. We thought about making something motorized, but decided against it because we want to keep it all mechanical. We also considered modifying the board itself to make it easier to get the balls off the board, but I think what we ended up making is better. I made something like the drinking straw idea several of you suggested. It looks like this:

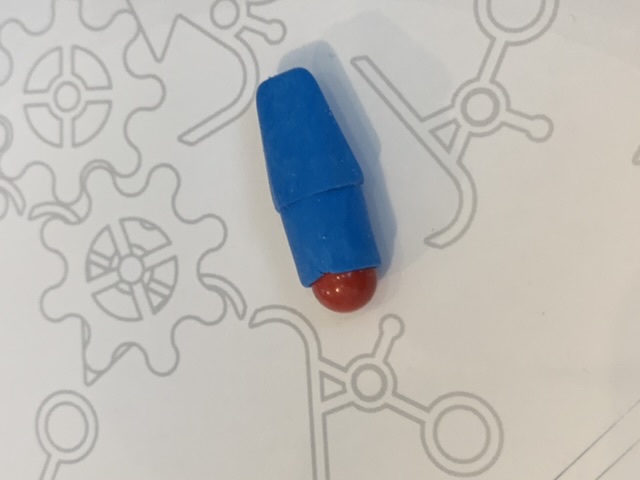

You push it down over a ball and the ball pushes by the rubber band, but doesn’t come back out. You can keep pushing it over balls to pick up more. You can also see how many balls you have in the loader by looking through the holes in the side. Here it is in action:

We’re going to make injection molds for this and have it available on our website, but it will take at least a few months before it’s ready. In the meantime, you can 3D print your own. Here’s everything you need:

Rubber band:

The rubber band is a #31 size (2.5" long, 1/8" width, 1/32" thick). You can find it (or something very similar) in pretty much any pack of assorted rubber bands.

STL files:

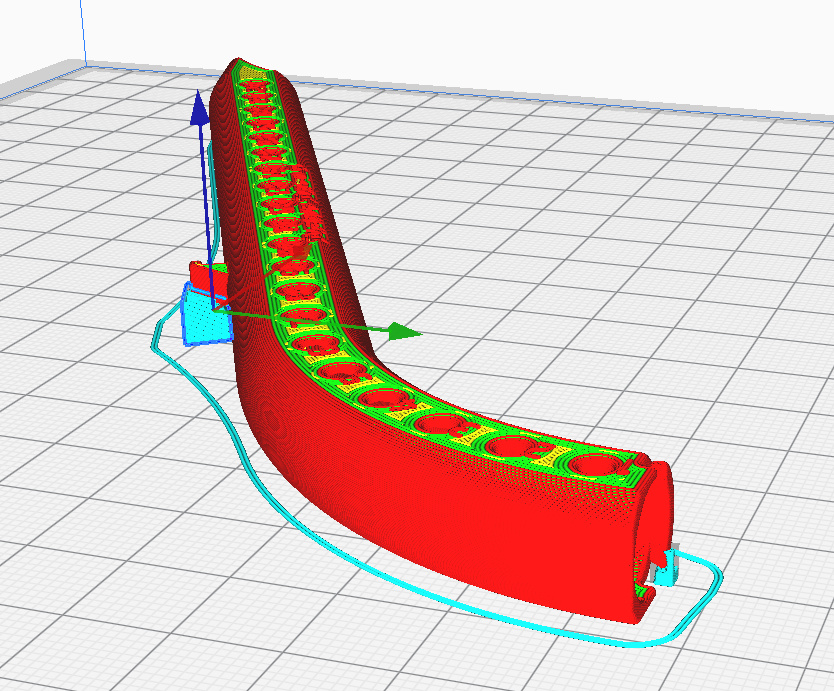

I have two options for you. If you have a 3D printer with a dual extruder, you can print the whole thing in one shot, using PVA for supports, and then you can wash the supports away afterward. Here is the STL file for that:

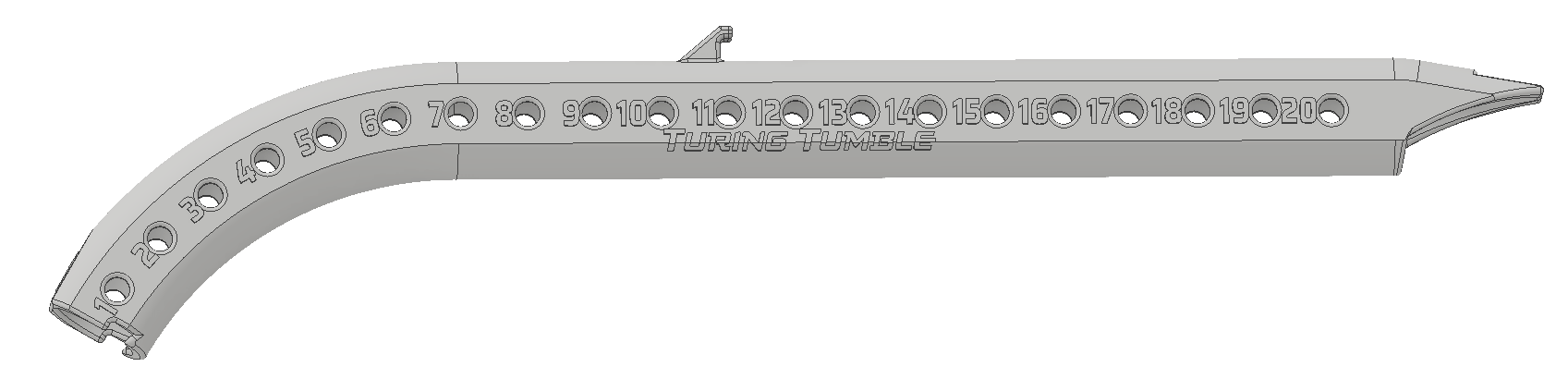

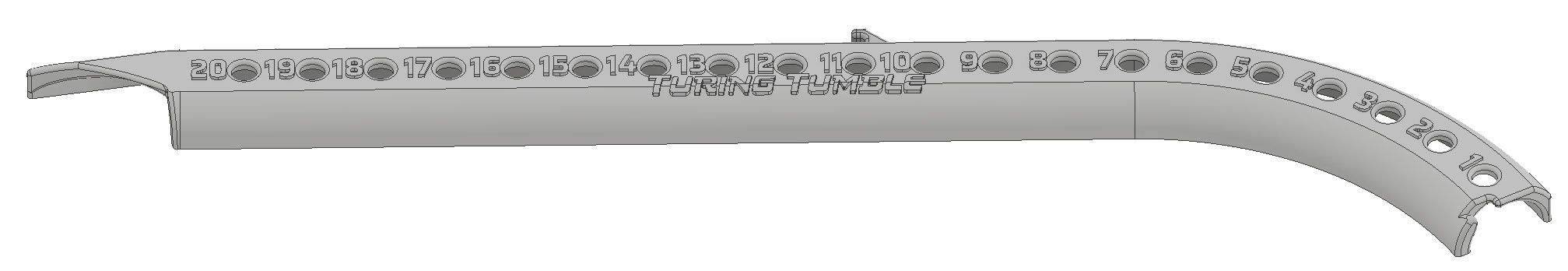

If you have a single extruder (most 3D printers are like this), then you’ll probably need to print it in two sections. Otherwise it would be very difficult to clear out the supports inside the tube once it’s finished printing.

Here’s the ball reloader split in half:

20181012 Ball Reloader Half 1.stl

20181012 Ball Reloader Half 2.stl

What do you think? We haven’t started making injection molds for it, yet, so if you have any ideas to improve it, we can still make changes.

Thanks again for all the great ideas!

Paul