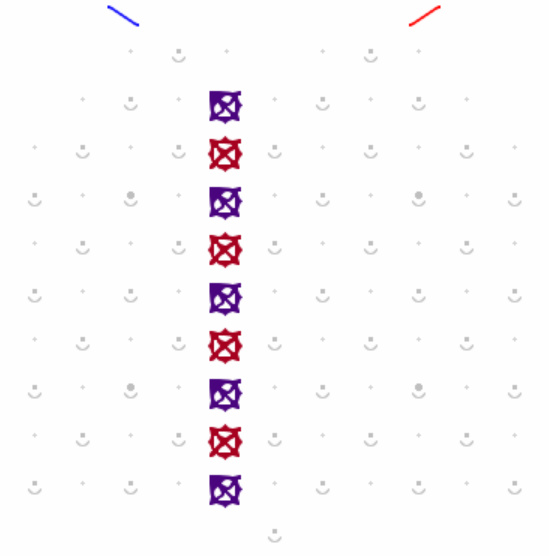

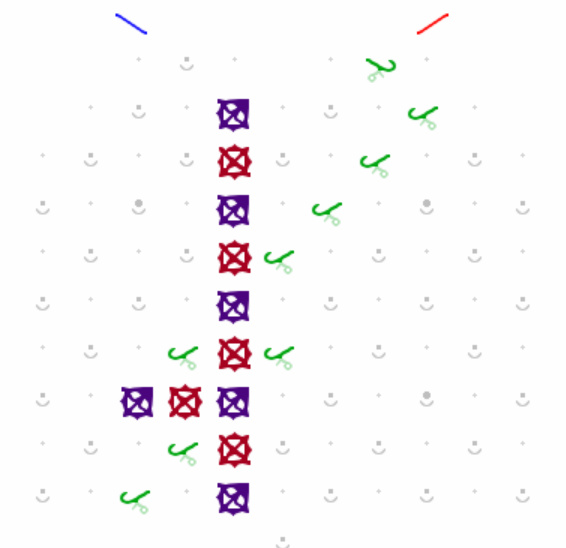

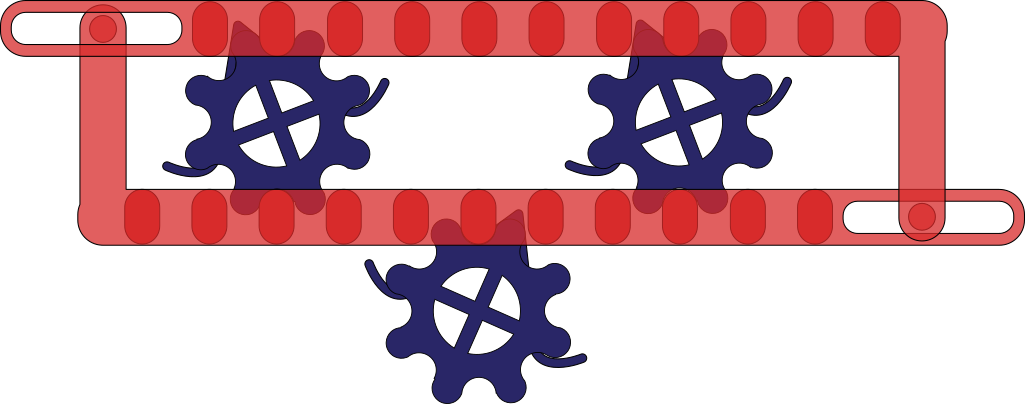

This is something I’ve been trying to figure out for a while. Gear bits are a critical component of the marble computers. If you can’t send information across or back up the board, you greatly limit what the computer can do (it’s no longer Turing-complete).

The gear bits in Turing Tumble have some major limitations, though. You can’t really have more than about 4 or 5 gear bits in a row before they stop working correctly. Part of it is that there’s some backlash in the gears that increases the more gear bits you have in series. The other problem is that the balls aren’t heavy enough to overcome the friction of turning that many gear bits at once.

For the size of the board in Turing Tumble, those aren’t big problems, but if you had a much larger board, you’d have to build some extremely inefficient circuits to overcome the limitations. Half your board space and several balls would be required just to send one bit of information from the bottom to the top.

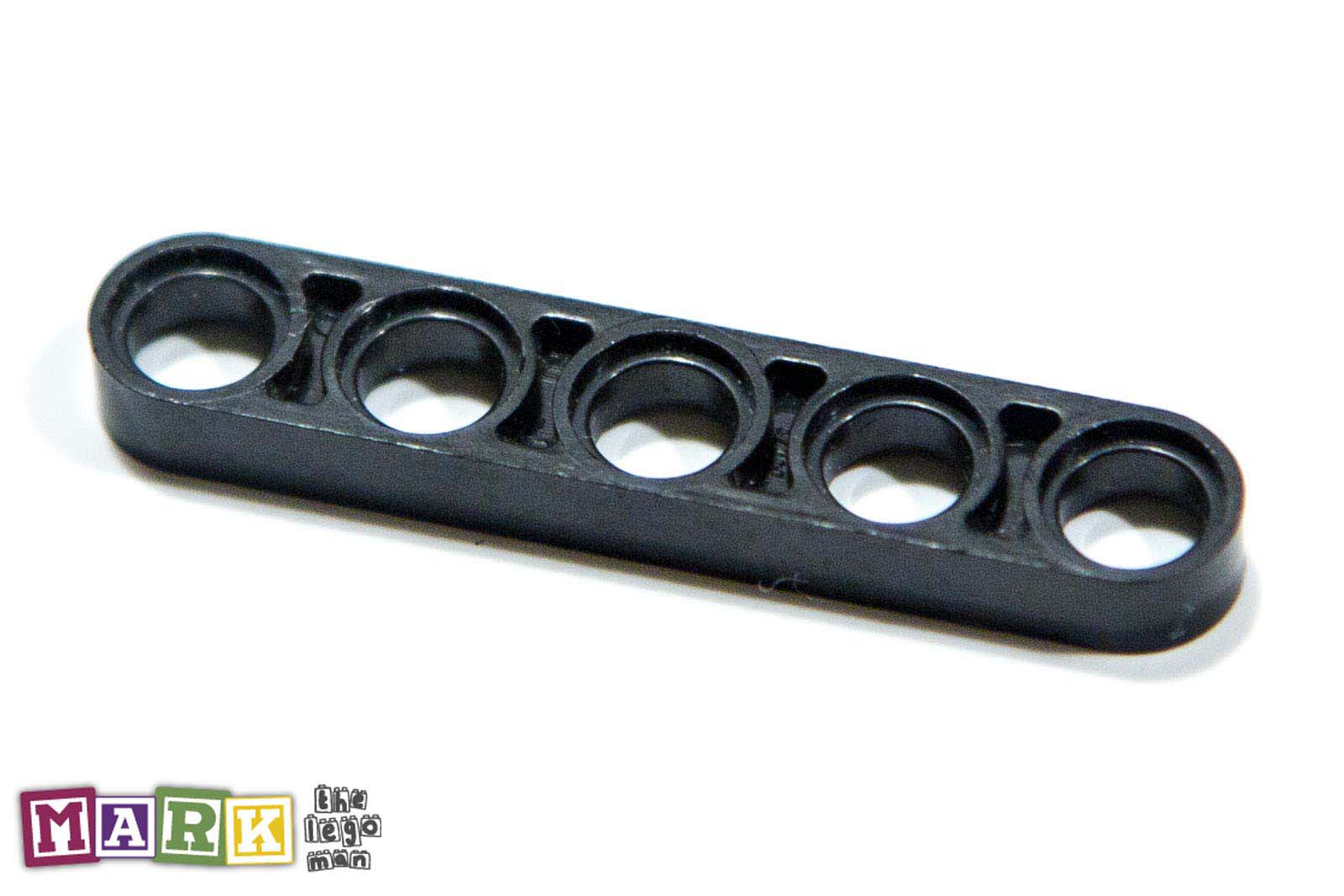

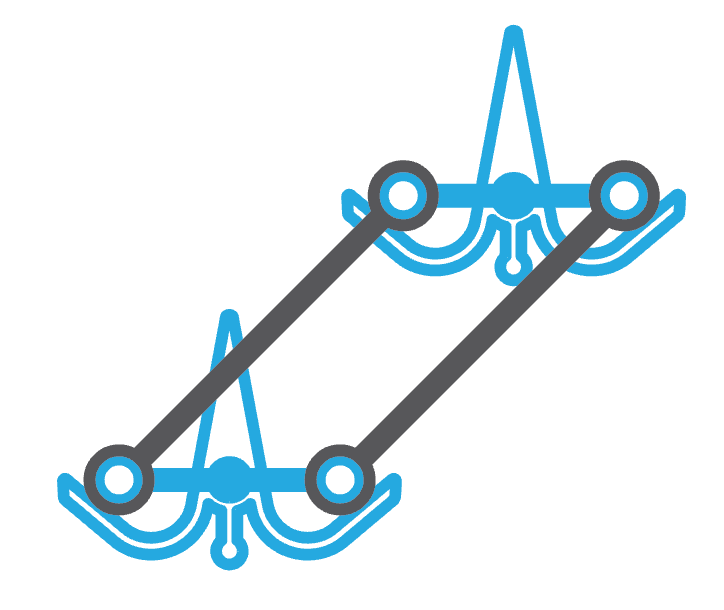

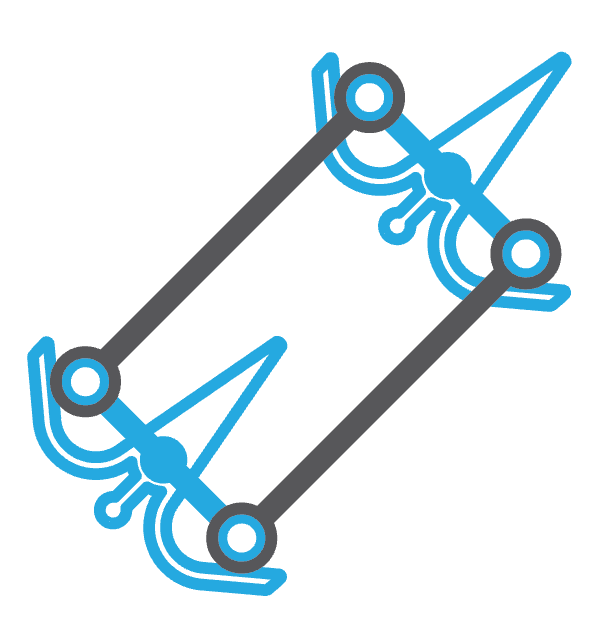

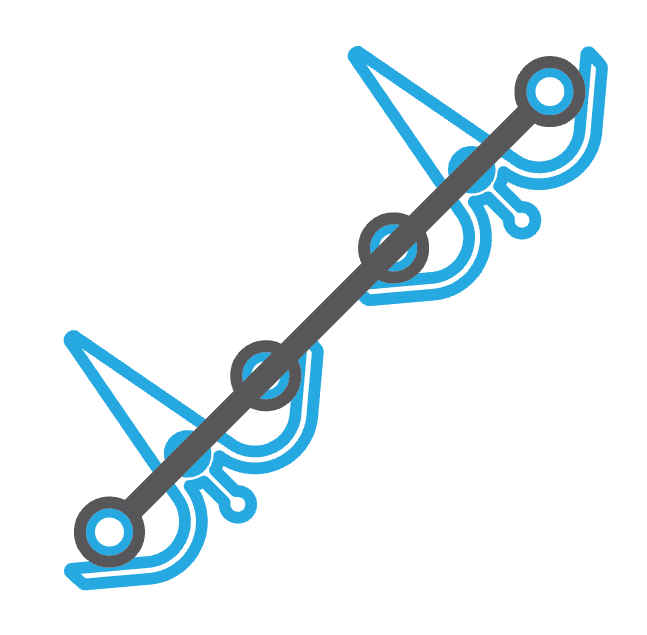

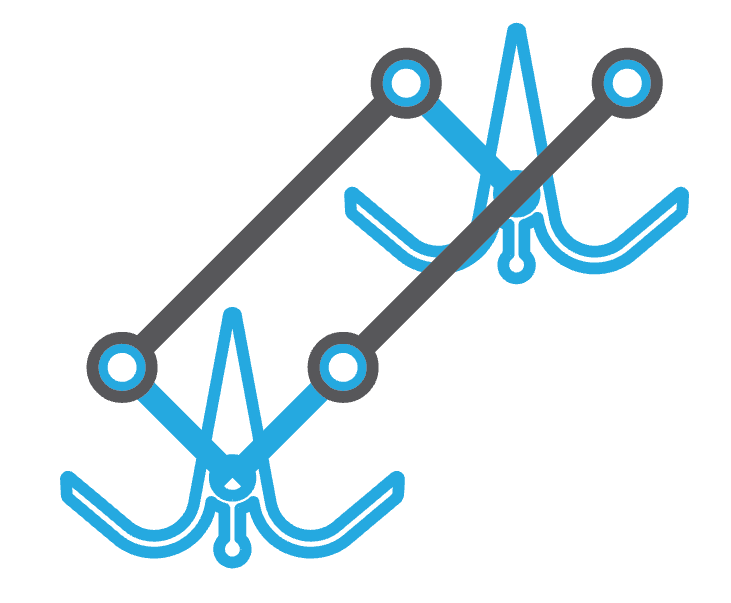

Can you think of a better way to connect bits together over long distances? The most obvious solution would be to make bits that are connected by thin strings. I’m sure it could work, but the hassle of tying little strings to bits would drive me crazy, and I’m sure the string would stretch out and get some slack in it over time, so you’d have to retie the string on a regular basis to keep the computer functioning.

Here’s the big challenge:

How could a long-distance bit connection be made in a way that’s a snap for people to add to the board and reliable?

And then the next challenge is:

How could it be made in such a way that one bit could be connected to not just one other, but several other bits without getting bogged down by friction?

I spend a lot of time in the shower thinking about these…

)

)