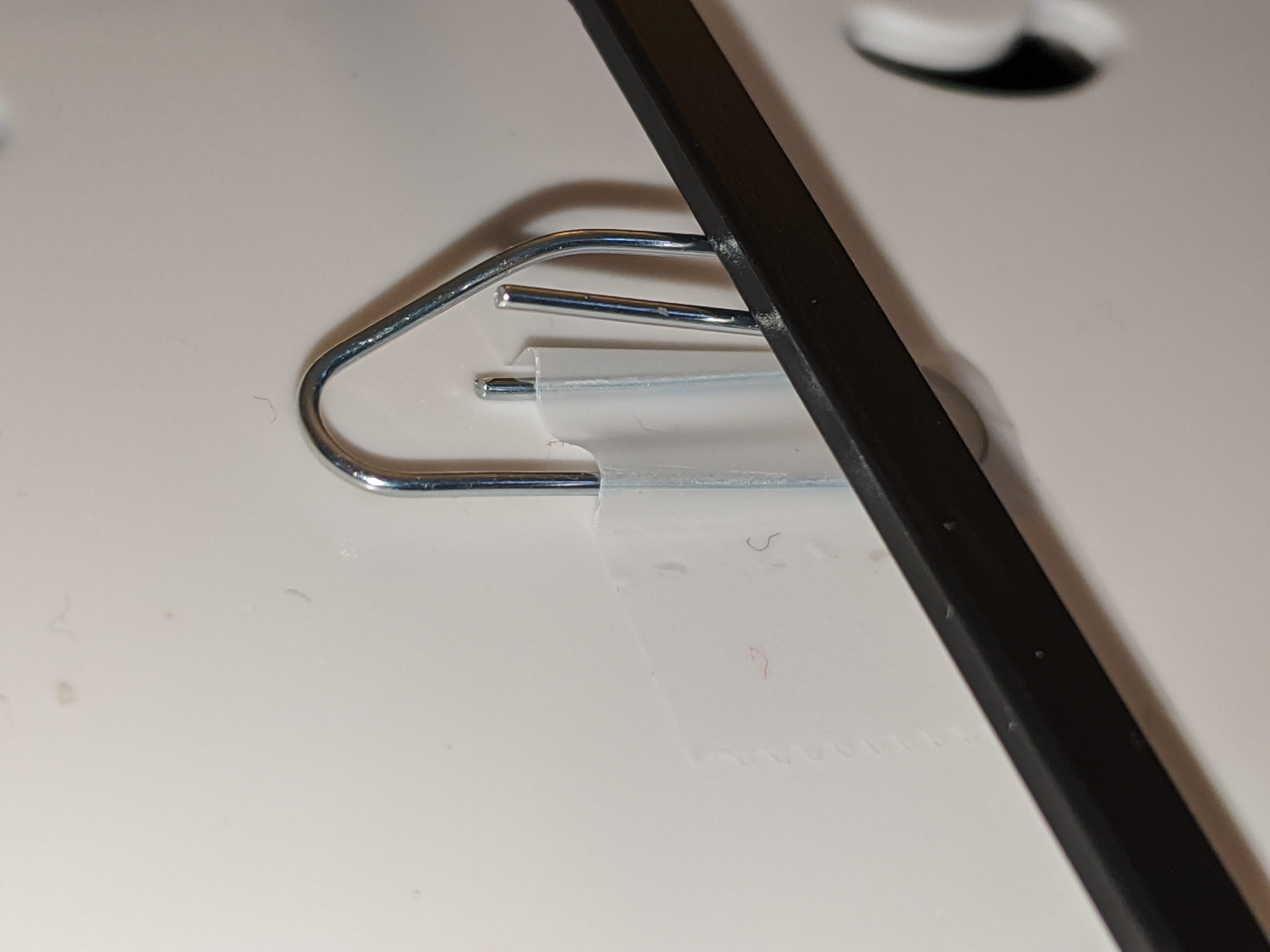

The long strap connectors are touching the back of the board, and if you put pieces on 2 specific pegs on either side, they get caught up when they try to rotate. The kind folks at TT are sending new connectors in case they are bowed, but I don’t think that is it. Is your board ever so slightly bowed? Anyone else with this issue? !

!

ETA: Just found this post that describes the same issue. Bit can not move in one place - #6 by paul